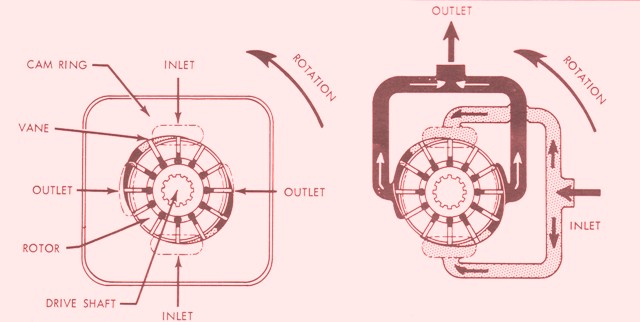

In the diagram below you will see how the fluid flow is done in the pump cartridge. The rotor is determined by the ring that is beside the driveshaft, that is latched onto a power origin. When the rotor turns, the centrifugal force on the vanes makes it to where it goes behind the elliptical inner surface of the ring. Then the radial action of the vanes and the rotor goes round it makes the chamber that goes in between the vanes to go up when the vanes proceed to the inlet parts of the ring. The outcome is a low pressure that lets the atmospheric pressure to make the fluid go into the chambers.

When the fluid is confined in the vanes and taken past the larger section of the ring. The outlet part is taken on, the ring diameter goes down and the fluid is made to go out thru the system. The system pressure is made to go under the vanes, making sure it is sealing contact goes up against the ring while it is in regular operations.

Hydraulic balance is made when side loads on the shaft zero each other out. The pump ring is made to be diametrically so that the two pumping sections will be opposed.

If you need more info on the pumping cartridge or anything else on the vane pumps, give us a call at 662-871-8403. You can email us at [email protected]