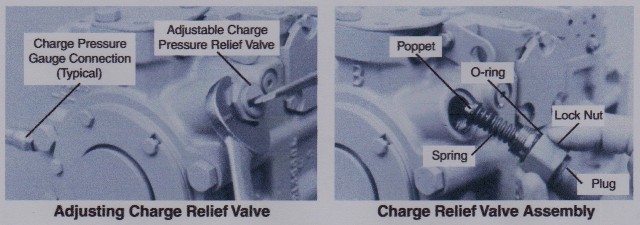

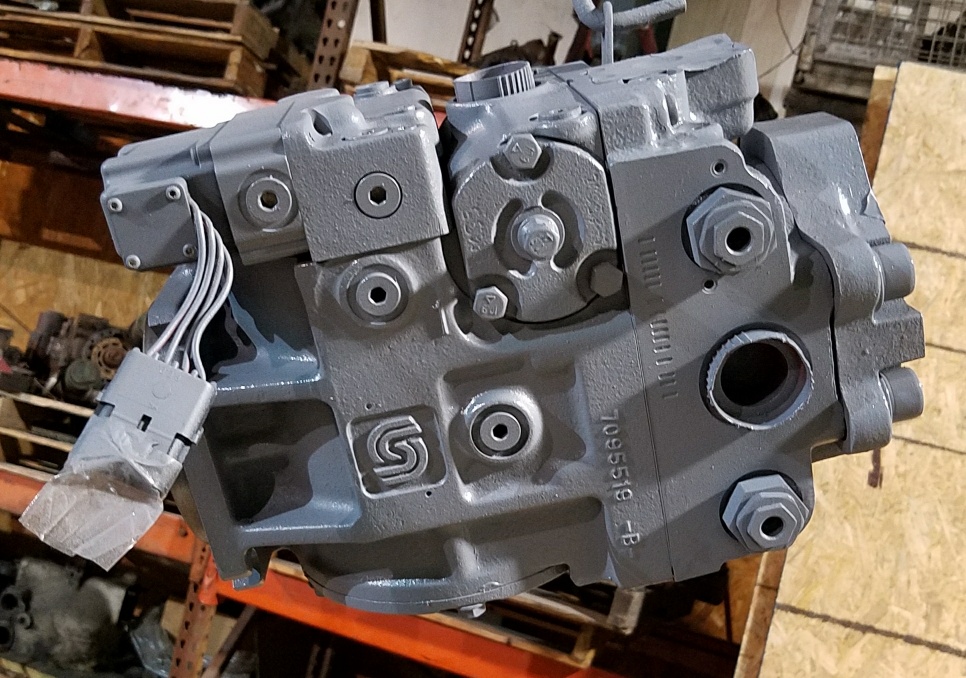

Sundstrand Series 90/55cc Charge Relief Valve

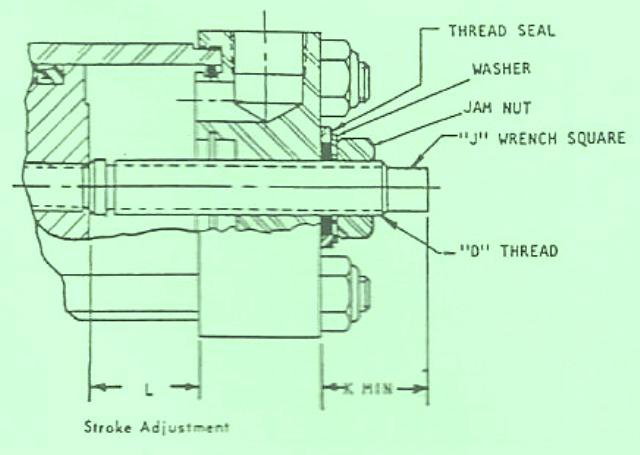

They are making the charge relief valve adjustable in a wide variety of pressure changes that are for 290m 348 and 406 PSI. It also changes the poppet and plug. It may stick out from the pump end cap alittle more than the older model. You will need to put in a gauge to tell […]