If your unit uses a lip seal, the kits has a shaft seal, retaining ring and spacer. You will only need the spacer if you have profound use out in the field. The spacer has the seal in a different place on the shaft sealing region.

Before you install this, make sure the shaft sealing face and the housing sea bore have been cleaned thoroughly. No dirt or debris need to be on there or it will have contamination all thru the unit.

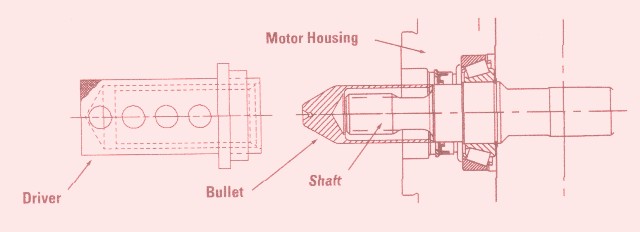

First you will need to grease the inside region of the seal that meets up with the shaft. Have the right bullet and it will need to match up right so you there is no opening within the bullet and shaft. The bullet needs to navigate on shaft diameter so it can’t shift side to side.

Push the new shaft seal(with grease on it) over a shaft bullet, on the closed face of the shaft seal and is toward the closed end of the bullet. Next you will need to put the bullet over the drive shaft so that it goes into the seal pocket. Align it up with the housing bore as you push easy as not to break the seal.

Use a mallet or something like it to press the seal in til it bottoms on the pilot of the flange. Take out the tool and put it in the retaining ring to it goes in the seal pocket.

If you need more info on this call us at 800-361-0068