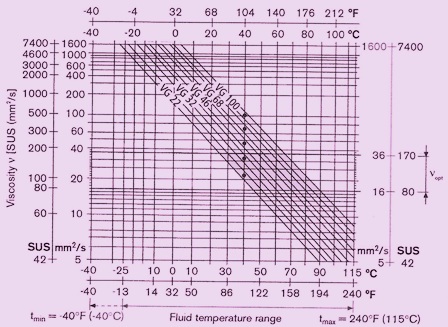

Limit of viscosity range

For operating applications you will need to follow these guidlines:

nmín = 60 SUS (10 mm2/s) for not so long periods (t £ 1 min) at max. perm. The fluid temperature of 239 °F (115 °C). Make a note that the max. leakage fluid temperature of 239 °F (115 °C) doesn’t go over these guidelines (for instance bearing area). The fluid temperature in the bearing area is approx. 7 °F (5 K) greater than the normal leakage fluid temperature.

nmax = 7500 SUS (1600 mm2/s) for not so long periods (t £ 1 min) on cold start p £ 435 psi (30 bar), n £ 1800 rpm, tmín = -13 °F (-25 °C)At temperatures between -40 °F (-40 °C) and -13 °F (-25 °C) special implications are needed.

Selection of the Hydraulic Fluid

The correct fluid, you will need to know the working temperature in the tank (open circuit) in relation to the current temperature. The fluid needs to be chosen so that the working temperature range, the viscosity lies within the best range (nopt), the shaded section of the selection diagram gives details. We suggest the higher viscosity grade in each case.

Example: at an current temperature of X °F (X °C) the working temperature in the tank is 140 °F (60 °C). In the best viscosity range (nopt; shaded area) this relates to viscosity grades VG 46 resp. VG 68; VG 68 would need to be chosen.

Note: The leakage oil (case drain oil) temperature is swayed by pressure and input speed and is always greater than the tank temperature. No way the circuit should go over 239 °F (115 °C). If this can’t happen for some reason with the above recommendations because of extreme working parameters or high outside temperatures, you should consult with someone about it.

Filtration of fluid

The finer the filtration the better your unit is cleaned,the pressure fluid will have longer life of the axial piston unit. Making sure you have a stable functioning axial piston unit, a minimum cleanliness of 20/18/15 to ISO 4406 is needed. At very high temperatures of hydraulic fluid (195 °F (90 °C) up to max. 239 °F (115 °C)) at least cleanliness of 19/17/14 to ISO 4406 is required.

When you use HF- or recommended fluids, read over all the limitations of the technical data As always call upon up to recommend fluids to use in your unit or to clean your parts. We are here to answer any questions you may have.

Call us at 800-361-0068