Hydraulic Jacks

What You Get

With over 40 years combined experience, we have the ability to help you with all your hydraulic jack needs.hydraulic pump needs.

- Excellent Customer Service

- Fast Turn Around Time

- Warranty Coverage

specializing in Hydraulic pump repair

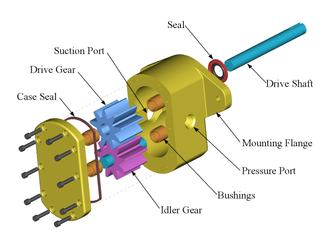

As the gears rotate they separate on the intake side of the pump, creating a void and suction which is filled by fluid. The fluid is carried by the gears to the discharge side of the pump, where the meshing of the gears displaces the fluid. The mechanical clearances are small— in the order of 10 μm. The tight clearances, along with the speed of rotation, effectively prevent the fluid from leaking backwards. The rigid design of the gears and houses allow for very high pressures and the ability to pump highly viscous fluids.

Gear Pump Exploded View

External Gear Pump

Internal Gear Pump

Gear Pump Applications

Learn more by clicking below

- Barber-Greene Pavers Sundstrand Hydraulic Gear Pump Repair

- Blaw-Knox Pavers Dynex-Rivett Gear Pump Repair

- Bomag Rollers Linde, Rexroth, Poclain Gear Pump Repair

- Case Backhoe Webster, Commercial Gear Pump Repair

- Case Track Loaders Sundstrand Gear Pump Repair

- Case Dozer Sundstrand Gear Pump Repair

- Case Wheel Loader Commercial Gear Pump Repair

- Case Excavator Linde, Kawasaki Gear Pump Repair

- Case Skid Loaders Sundstrand Gear Pump Repair

How does a gear pump work

Gear pumps (with external teeth) (fixed displacement) are simple and economical pumps. The swept volume or displacement of gear pumps for hydraulics will be between about 1 and 200 milliliters. They have the lowest volumetric efficiency of all three basic pump types (gear, vane and piston pumps)[1] These pumps create pressure through the meshing of the gear teeth, which forces fluid around the gears to pressurize the outlet side. For lubrication, the gear pump uses a small amount of oil from the pressurized side of the gears, bleeds this through the (typically) hydrodynamic bearings, and vents the same oil either to the low pressure side of the gears, or through a dedicated drain port on the pump housing. Some gear pumps can be quite noisy, compared to other types, but modern gear pumps are highly reliable and much quieter than older models. This is in part due to designs incorporating split gears, helical gear teeth and higher precision/quality tooth profiles that mesh and unmesh more smoothly, reducing pressure ripple and related detrimental problems. Another positive attribute of the gear pump, is that catastrophic breakdown is a lot less common than in most other types of hydraulic pumps. This is because the gears gradually wear down the housing and/or main bushings, reducing the volumetric efficiency of the pump gradually until it is all but useless. This often happens long before wear causes the unit to seize or break down.