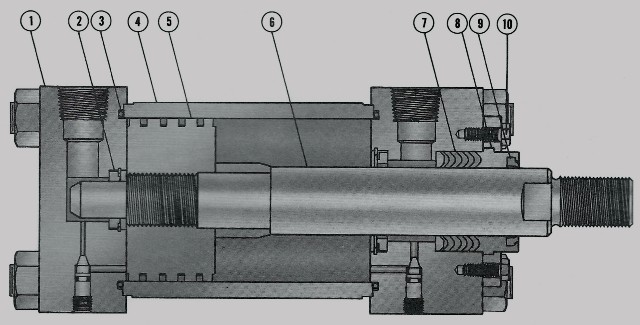

Number One: Face Ground and raised endcaps that are from ASTM A 108-61 C1117 substance. It will give a parallel and square area for machining, putting it on and stable alignment.

Number Two: The seal on the cylinder is on there securely, to prevent leaks.

Number Three: The tube is pilot fitted and goes right up next to the torquing facade to let you know the oring that goes in the tube is seal properly.

Number Four: The steel tubing is straightened out ahead of honing. The larger honing stones give it a more smoother and straighter process of operation.

Number Five: The piston on the cylinder is all inclusive that has a pilot is suitably on the rod with loctite (6″ bore) or by putting screws in on a longer of 7″ or more. The thread diameter will change the every time the rod diameter changes, so it will give you a better bond that is tight.

Number Six: These are chrome plated rod to prevent so much wear and damage.

Number Seven: There are pressure sealing lips by way of male seal adapter. The metal adapter gives support on the rod and rod end of cylinder gets serviced.

Number Eight: On the SAE 660 bearing has a bronze finish to help with breakage in all different types of conditions, so your use of the cylinder is a smooth one. Most other companies offer iron and it will break in colder climates.

Number Nine: This is a rod cartridge you can take out. You don’t have to ease up on the toque on the tie rods.

Number Ten: The rod wiper has extra abrasion resistance that other companies have on their cylinders so there is no down time on the job.

When you come by to order cylinders, you will need to know some info before coming by the shop:

Series and Mounting Style Rod End Style Bore Size

Rod Diameter Stroke Pressure and Fluid

Cushions if you need any Modifications you may need

Call us at 662-871-8403 or email us at [email protected] with any questions you many have. And give us a call with a quote as well.