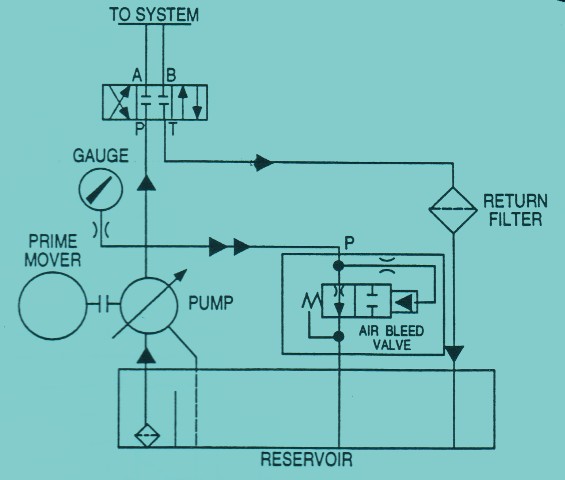

On these units the air bleed valve gives the pump more loading or start up when there is a dead setting. It opens to let in oil and air to let it pass from the inlet to the outlet and let it go back to the reservoir. When pressure is in the spool center section is bled by means of spool clearance it goes to the non spring end of the spool. When pressure hypes up, it controls the spring, shafts the spool to shutoff the inlet port and lets the full pump flow to the circuit.

When there is air in the circuit the valve is made to remove it. It stops the flow thru in a matter of minutes. This is used in an electric motor prime mover. When you use an engine prime mover the valve delivers flow for just a minute letting the internal combustion engine to get up to speed, so it can get rid of a different open center valve to be used for that purpose. Also, you will need to have the outlet line piped in under the oil level to make sure it doesn’t foam up the oil.

If you need questions answered about this valve or bleeding air out, call us at 800-361-0068