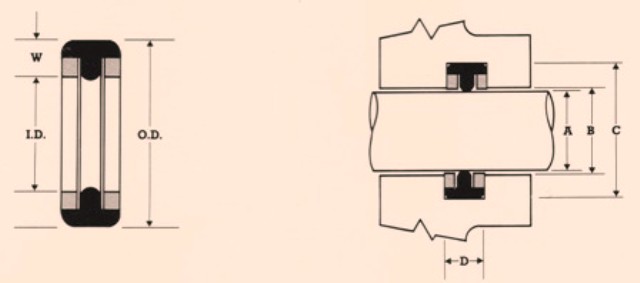

It is essential you know certain things before getting seal for whatever unit you are working on. You will need to know the pressure range, temperature range, maximum diametrical clearance and seal width. The main reason a seal wears out is the clearance gap. They can be pinched or cut into, if not seated properly. So make sure you know what you need to do the job correctly.

T seals are more compact than your usual seals, will fit in the groove better. They are a compressed seal so it is more reliable in double acting applications. And it is more compressed so that doesn’t allow low pressure leakage. These types of seals make use of the hydraulic pressure to make sure the seal is engaged with the rod or cylinder wall, which in turn doesn’t let extrusion happen.

They are made to deal with low pressure leakage, but the stand in ring rest in between the seals flanges and the rod or bore so it want cause any damage to the seal or rubbing it also.

T seals doesn’t allow spiral rolling to go on when the piston or rod movement occur. And even when low pressures let in the backup rings that are locked into the sealing element to stay in place.

These types of seal are good for off road equipment, farm machinery, hydraulic valves, pneumatic equipment, industrial machinery and so much more.

If you need more info on different types of seals and what is best for what application. Give us a call at

662-871-8403 or email us at [email protected]