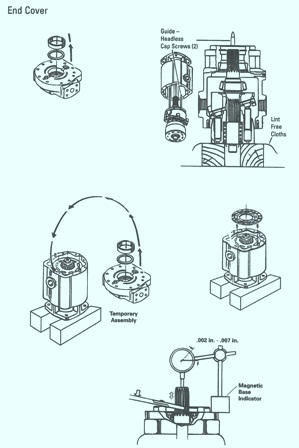

Put in two dowel pins and a gasket on the cover. Put some grease on the bearing shims and bearing cup and put in the cover. Next check the output shaft for end play. Put the end cover in, but don’t put in the valve or bearing plates yet. This helps with the spring tension up next to the output shaft.

Put he cap screws in, tighten them up evenly. The support motor assy goes next, but tap the output shaft inward, but tap easy. Put in the magnetic base indicator on the mounting flange so the gauge on the output shaft, use a tool to put it in as low as it will go. You will need to open it upwardly to make sure the shaft doesn’t have end play in it. Needs to be .002 – .007 inches of play in it.

If you don’t get it right, do it again by giving it the correct amount by taking out shims that are under the bearing cup.

When you get that right, put the motor on the mounting flange and take out the end cover. Put the two dowel pins in the face of the cylinder barrel. Put grease on the bearing plate and put it on the cylinder barrel sub assy.

If you need further help with this, call us at 662-871-8403 or 800-361-0068