The pistons cups main job is a piston head, plunger or ram in the hydraulic or pneumatic function. The sealing surface goes to the borders edge. This is best worked in construction equipment, industrial machinery, mining, farm and off road equipment.

Piston cup packing doesn’t need a machine to do the recess that is needed. It is put in so it goes right next to the piston head. It has a follower plate is within it. Works great whether it is high or low pressure. Has great longevity. It can handle low pressure whether it is in air, water, hydraulic fluids and grease. These types of seals irregular since they are static sealing lines are not your usual shape. When it is put under unusual pressure, they are still stable even when they are put in gland or a clamp that goes into the piston.

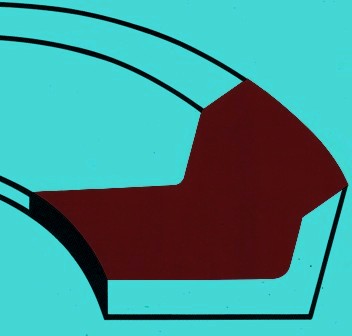

Most of the single acting cylinders like hydraulic rams, have to depend on mechanical ways to bring in the rod or push it out. The picture shows a pneumatic model that has a spring to make the rod go out and uses pressure to make it go back in. The gland expansion helps safeguard to oppose damaging the piston cup while the rod is out. It also can help in not allowing the air inlet by going over toward the cup lip and when the extension is smaller having the piston nut protects it from damaging the return spring.

The packing for the double acting piston is put in back to back right up next to the backing plate. This type of unit is a follower plate so that it can compress the static seal. A plate is included for the piston head. When you put the packing in, it needs to have a backing plate go between them.

The piston cup that is connected to the ram that doesn’t have a backing plate (it is separate). The cylinder needs to be close tolerances and the ram of a certain size that can be worked to leave the lest amount of working clearance that goes between it and the cylinder wall. When using this type of packing and depending on the jobs it does, it can get worn out pretty quickly, the unit will not work at its best. Hell clearance needs to have all the pressure it can get so it is not supported by the thin area. Make sure your clearance is between the piston and cylinder wall so there is no extrusion on the heel cup.

IF we can assist you with packing, seal or more information on this subject, call us at 662-871-8403